Step 1

Each Heat Exchanger will be properly logged in and assigned a W.O. # to follow the plate pack throughout its time at our facility. This will enable the customer to have access to information at each stage, and customers can use RossHX's Real Time Tracking to monitor the progress. This process also ensures no mixture of other customers' plates.

Ross HX Online Order Tracking

Real Time Online Tracking

To track your order please enter your Order ID in the box below and press the "Track" button. This was given to you on your receipt and in the confirmation email you should have received.

Step 2

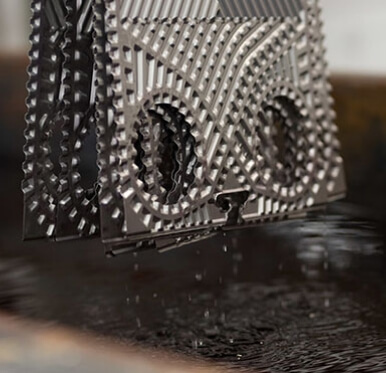

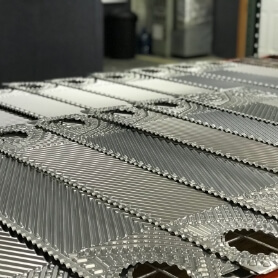

Each Heat Exchanger plate will then be pre-rinsed before entering our nonabrasive cleaning process.

Step 3

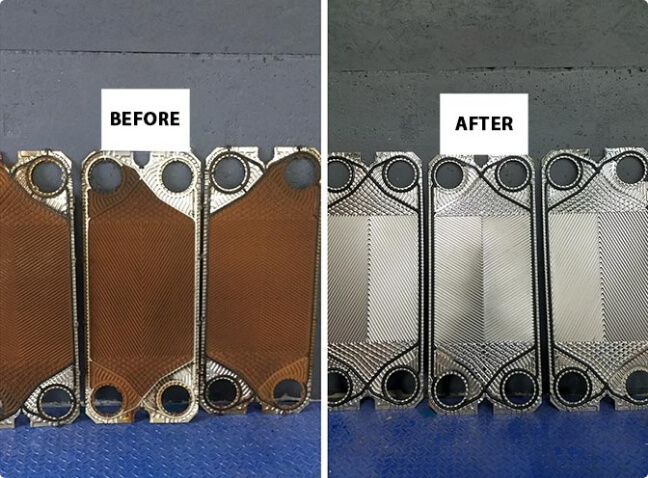

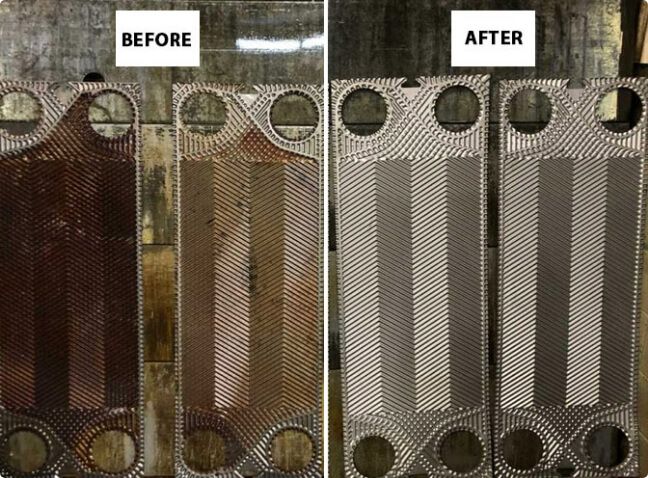

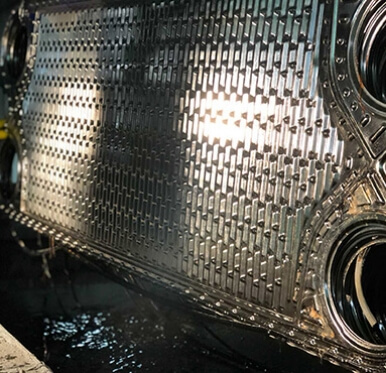

Our non-abrasive cleaning process will clean and restore your plates by removing product buildup and water deposits. Each tank will be fully charged and heated, ensuring quicker processing.

Step 4

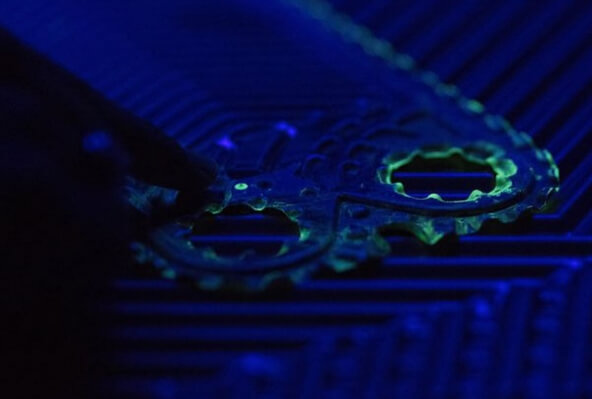

Each Heat Exchanger plate will then enter the "dye penetrant" process for proper dye penetrant leak testing.

Step 5

Each Heat Exchanger plate then enters the dye quality check. This process will help identify and locate cracks and/or pinholes that allow cross-contamination. Guaranteed testing of each plate is a must unless otherwise directed by the customer.

Step 6

Each Heat Exchanger plate will then enter the "re-gasketing" stage. This process may vary from customer to customer, depending on the adhesive that best fits the customer's needs. However, the attention to detail will remain the same. RossHX can also use a two-part epoxy per the customer's request. This step will add additional time as each plate will need to be properly assessed with a jig and put into the oven for proper curing.

Each Heat Exchanger plate will then enter the final stage of "quality control". This is where they are inspected and packaged for return to the customer. If the customer provides the plate arrangement, RossHX will make sure each plate pack is put in order for easy installation.

Step 7

Each Heat Exchanger plate will then enter the final stage of Quality control. This is where they are inspected and packaged for return to the customer. If the customer provides the plate arrangement, RossHX will make sure each plate pack is put in order for easy installation.